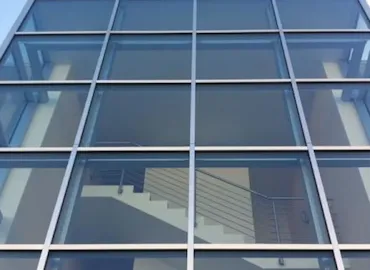

If you do not choose the right material and type, windows can be an important factor in energy loss in buildings, energy loss in aluminum double-glazed windows is much less than iron windows. Also, the lightness, beauty, and durability of aluminum double-glazed windows are completely superior to other windows. For this purpose, aluminum windows can be considered the best type of window. The aluminum window panel, with its great variety in form, color and wide use of fittings, and variety of opening, has met the standard needs of the construction industry. In summary, all the benefits of using an aluminum window can be listed as follows: Relative thermal insulation, waterproofing, sound insulation, non-occupational, environmentally friendly and recyclable, resistance to air pollution and dust, resistance to wind pressure at the same time light, beautiful, a variety of colors and desirable, resistant to discoloration and deformation (due to environmental factors such as sunlight and electrostatic powder paint); with over 200 different colors. However, another coating and painting panel, namely anodizing, would apply for aluminum profiles. Aluminum profiles with printed colors and hardness in the furnace are doubly durable and beautiful.